We deeply understand the practical needs of users for stable efficiency enhancement. We offer five types of full - life - cycle management services for frequency converters, including "spare parts reserve", "preventive maintenance", "in - depth maintenance", "aging component upgrade", and "overall replacement", to meet the personalized needs of our customers.

From the moment the equipment is sold, we will provide comprehensive support to ensure its efficient operation throughout the entire life cycle, helping you reduce costs and increase efficiency!

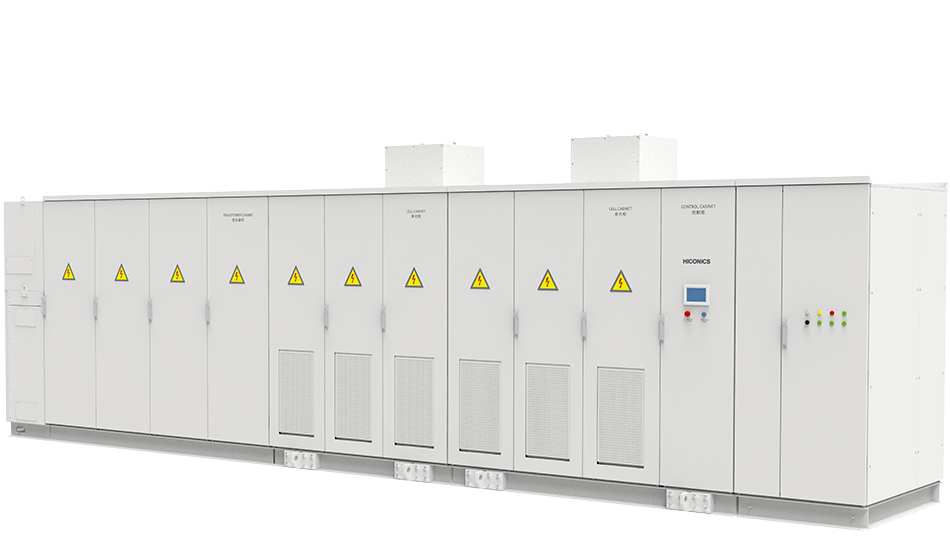

In terms of product design and development, Hiconics New Energy has a deep understanding of the practical needs of the industry. It uses innovative technologies and practices to solve application pain points. From applications in extreme environments, long - term stable operation, energy conservation and consumption reduction, safety assurance to intelligent operation and maintenance, it provides users with fully customized high - voltage frequency converter products. Up to now, it has served more than 5,000 customers, with a market inventory of 22,000 units. The application scenarios cover hundreds of industries such as cement, petrochemical, mining, power, light industry, metallurgy, and municipal services, winning unanimous recognition and praise from customers.