High Energy Consumption in Thermal Power Generation

The Demand for Energy-saving Transformation is Becoming Increasingly Prominent

As the largest auxiliary equipment in a thermal power plant, the feed water pump is restricted by the fixed speed of the motor. The feed water pump is characterized by "low output speed, low efficiency, and persistently high power consumption rate", which directly affects the economic and technical indicators and energy-saving benefits of the entire plant. Therefore, choosing a more reasonable energy-saving adjustment method for the feed water pump has become an important factor in ensuring the economic efficiency of the power plant.

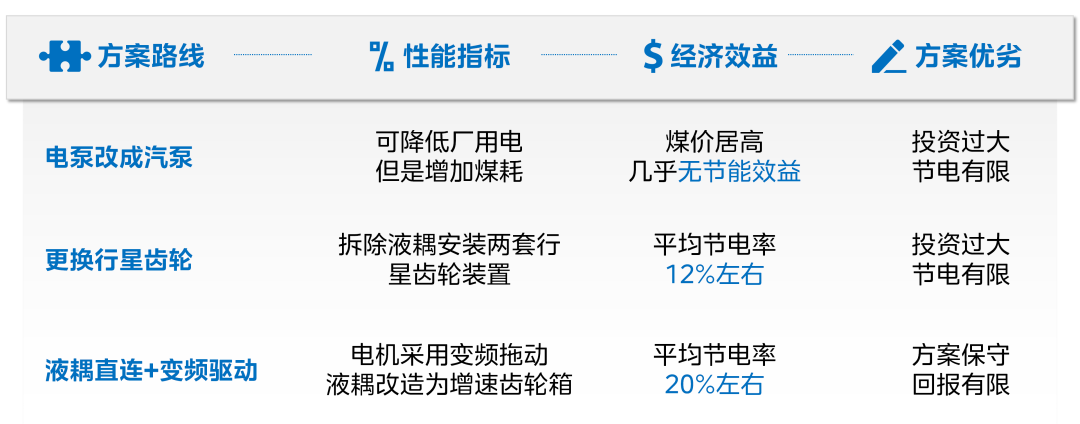

At present, there are mainly the following three solutions for the energy-saving adjustment and transformation of the electric feed water pump in China:

Currently, the three mainstream solutions on the market generally have the following disadvantages: huge upfront investment costs, minimal energy-saving benefits, long renovation cycles, and low return on investment.

Ordos Electric Power Co., Ltd. is subordinate to Inner Mongolia Ordos Electric Power and Metallurgy (Group) Co., Ltd. It is a large-scale thermal power generation enterprise constructed in accordance with the circular economy industrial model to achieve the local transformation of resource advantages.

The total installed capacity of Ordos Electric Power reaches 6×330MW + 6×135MW + 2×65MW + 2×50MW, and the annual power generation hours are basically over 8,000 hours. While providing sufficient power for the metallurgical and chemical systems of the internal circular industrial chain of the group, its operation level and profitability also rank among the top in the domestic industry, making it a well-deserved outstanding enterprise.

However, restricted by the structure of the electric feed water pump with a hydraulic coupling speed regulation used in the generator set, the technical level of energy conservation and consumption reduction is relatively low. In order to ensure that the power supply coal consumption of the overall unit can reach the advanced standard, there is an urgent need for an energy-saving renovation of the electric feed water pump. And since the project is related to the energy conservation and consumption reduction of the group, it has been put on the agenda as an important project.

Hiconics Technology Co., Ltd. undertakes the two-phase energy-saving renovation and upgrading projects of Power Company I of the Power Division of Ordos Group. At the beginning of contacting the technical team of Hiconics Technology, the project personnel of Ordos Electric Power Company were already very familiar with this team: there are more than 100 high-voltage frequency converters of the Hiconics Technology brand densely distributed in multiple power plants of Ordos Group. As an industrial frequency conversion expert, Hiconics Technology has applied a large number of frequency conversion energy-saving and upgrading renovation solutions in traditional industries such as coal power, mines, and smelting.

Directly on the Scene of Hiconics Technology's Project

There are over 22,000 high-voltage frequency converters of Hiconics Technology in operation in more than 30 countries and regions around the world. They help enterprises achieve refined process control, enhance the stability and operating efficiency of equipment, and provide crucial support for the path of efficiency improvement and intelligent transformation in these industries.

Breaking Technological Boundaries

Hiconics Technology Pioneers the 'Optimal Solution in the Industry

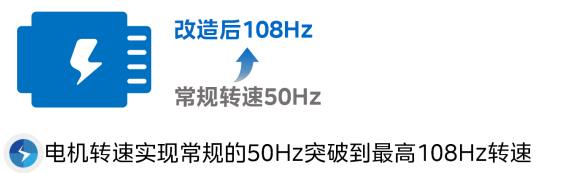

With its rich experience and technical strength in the field of energy-saving transformation in the thermal power industry, after in-depth communication with the staff of Ordos Electric Power and combined with the actual situation on site, in order to minimize investment and maximize returns, Hiconics Technology proposed the industry's first initiative - the solution of high-speed motor direct drive + variable frequency speed regulation.

It provides a brand-new high-efficiency energy-saving solution for the energy-saving transformation of high-power speed-regulating equipment such as feed water pumps. This solution is highly innovative and challenging. It breaks through the three conventional solutions under the mainstream cognition and, with breakthrough innovation, contributes the "fourth solution", which is also currently the "optimal solution in the industry.

Principle Analysis of the Solution of High-speed Motor Direct Drive + Variable Frequency Speed Regulation

The system architecture is innovatively developed, transforming equipment-based energy conservation into solution-based energy conservation.

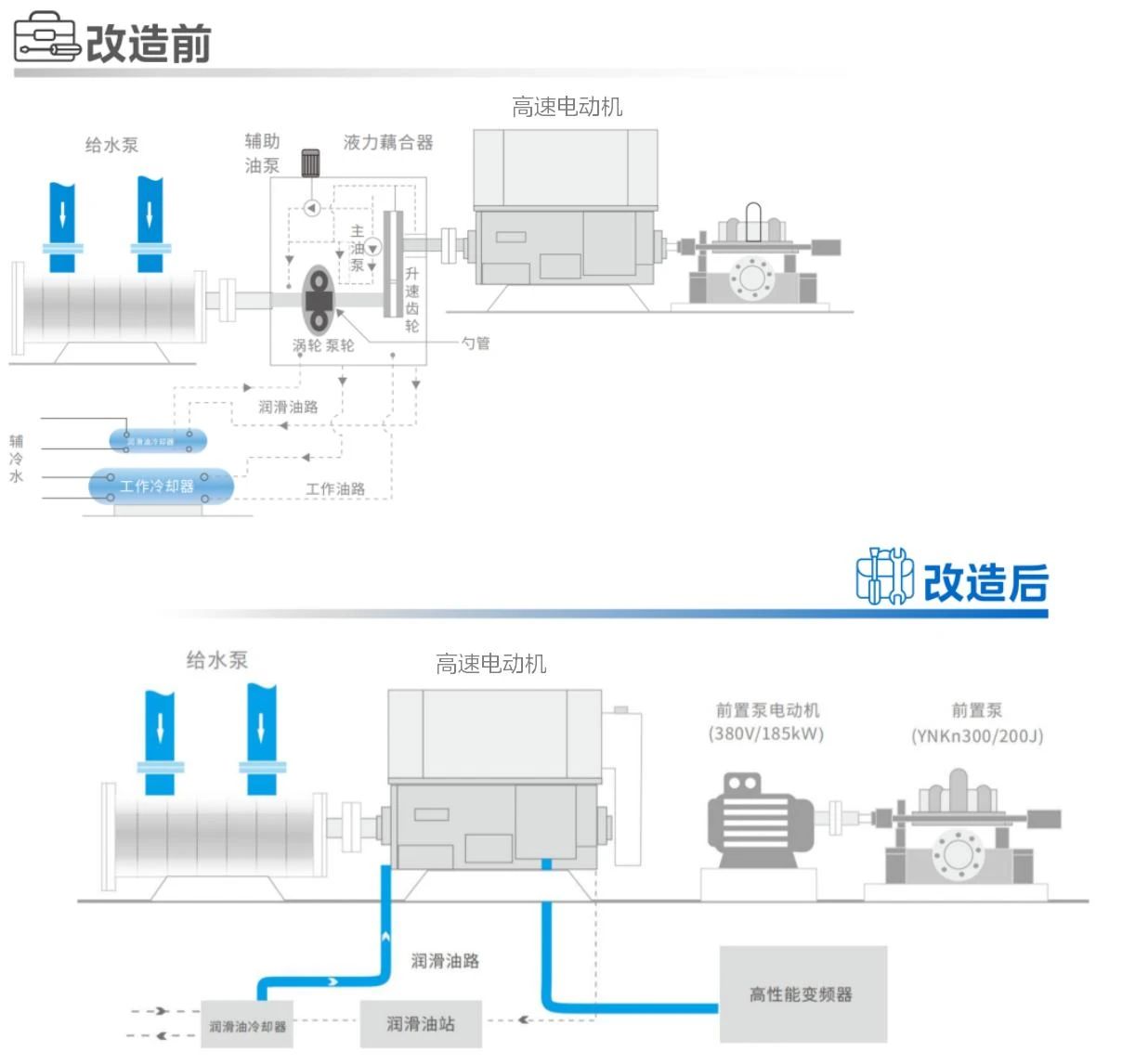

The high-speed direct drive variable frequency solution directly removes the hydraulic coupling originally used for speed regulation in the feed water system, completely eliminating the mechanical energy loss generated by the transmission of the hydraulic coupling.

Replace the original motor with a high-speed motor and directly connect it to the feed water pump. Then, through the high-voltage variable frequency speed regulation system, it is responsible for adjusting the speed of the high-speed motor, thus greatly improving the overall efficiency of the motor and the total operating efficiency of the entire pump unit.

On site after project renovation

From Product Output to Solution Capability Output

Comprehensively

Hiconics Technology carried out two phases of energy-saving transformation for the Coal Power Division of Ordos Group. The first phase was completed in 2021, and the first "Water-cooled High-voltage Frequency Converter Speed Regulation High-voltage Motor Direct Drive Electric Feed Water Pump" was officially put into operation.

The two high-speed direct drive variable frequency pumps operate stably and reliably, and the energy-saving effect is remarkable.

This data leads the entire industry

and has become a model for energy-saving transformation in the industry.

In 2024, four high-power water-cooled variable frequency devices were invested in the transformation of the second-phase project. After they were put into use, it is expected that the annual electricity saving cost can reach more than 9 million yuan, and the power consumption rate of the plant will decrease by 1.2%. This has helped the Coal Power Division of Ordos Group to significantly reduce its power consumption losses, simplified the complexity of personnel employment, provided a solid guarantee for the stable and efficient operation of the equipment, and enabled benefits to be realized in all aspects.

The energy-saving transformation of the Coal Power Division of Ordos Group has become the first domestic application case of the "Water-cooled High-voltage Frequency Converter Speed Regulation High-voltage Motor Direct Drive Electric Feed Water Pump", setting a precedent for the domestic application of variable frequency energy-saving transformation of high-power equipment. It has provided the "fourth solution", which plays a significant role in promoting subsequent energy-saving solutions in the industry.